Palletizing robot

- content:

Palletizing robots

Used for customer file production of bag products such as bran, cement, feed

Purpose: replacing loading and unloading workers, increasing labor efficiency and output

Ensure safety when stacking the pallet: change human strength, reduce the error of gas stacking bags on the pallet

The output meets: depending on the customer's line, 1 Robot can pick up about 30 tons / h with 25kg bags, 45-50 tons for 40kg bags

General requirements: The robot is designed for palletizing a production line with a capacity of 14 tons / hour.

+ Containers of feed products 25kg and 40kg

+ Pallet size 1500 x 1500 mm

+ Sorting specifications:

25kg bags: 8 bags / layer x 8 layers / pallet

40kg bags 6 bags / layer x 8 layers / pallet

+ The system operates stably and flexibly

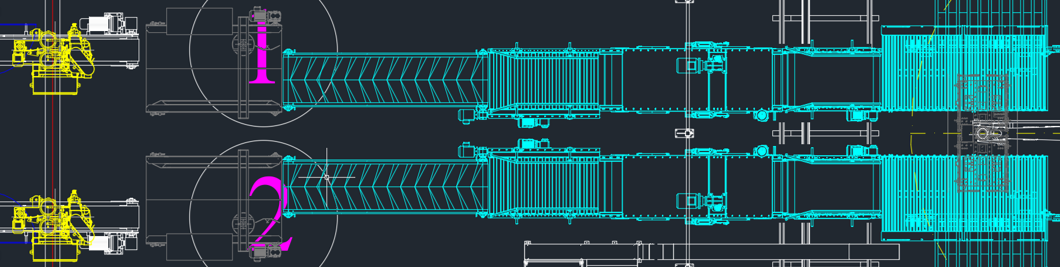

Equipment layout:

+ Palletizing robot system with a full range of equipment around, arranged as proposed drawing.

01 robot will work for 2 production lines, use 2 zone clamps to pick up 2 bags / cycle.

+ List of main equipment includes:

Bag folding machine and bag sewing machine

Bottom first set

Conveyor slope

Square roller conveyor

The bag presses adjust automatically

Conveyors pick up bags

Pallet feeder and empty pallet carrier

Full pallet conveyor system

Robot IRB 660 250kg

The 2-zone holster has automatic adjustment function

Electric control system

Security system

Modern 4-axis robot, working range 3.15m, maximum load of 250kg for packing problem: bran, cement, brick….